What is a brad point drill bit? This is a question that many people have, and it’s not surprising. A brad point drill bit can be a little confusing to understand at first glance. However, once you learn about the benefits of using this type of drill bit, you’ll be anxious to try one for yourself! In this article, we will discuss what a brad point drill bit is, the different types available, and how to use them properly. We’ll also answer some common questions that people have about these bits. So if you’re curious about Brad Point drill bits, keep reading!

What Is a Brad Point Bit?

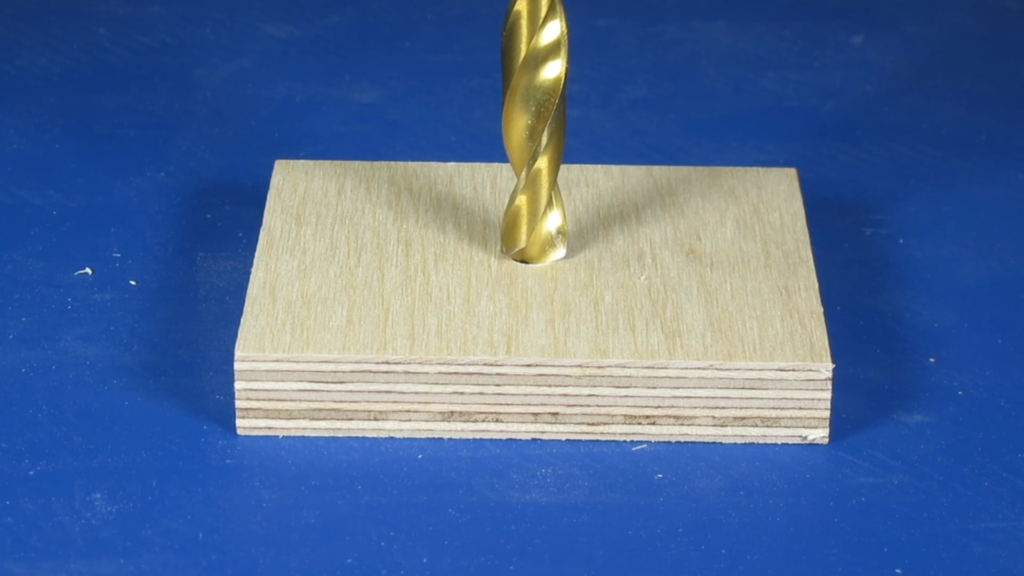

The point of the drill bit is sharp and comes to a fine point, which allows it to create clean, straight holes without splintering the wood. Brad Point bits are also known for being able to drill through knots and other difficult-to-drill areas of wood. [4]

Two Types of Brad Point Drill Bits

There are two types of Brad Point drill bits: those with a point and those without. The type of bit you need will depend on the material you’re drilling into.

If you’re drilling into wood, then you’ll need a bit with a point. This type of bit has a sharp tip that helps it to penetrate the wood more easily.

If you’re drilling into metal, then you’ll need a bit without a point. This type of bit has a blunt tip that helps to prevent it from slipping and damaging the metal. [1]

What brad points are used for

Brad point bits are used for precision drilling in wood, often for doweling. The brad point bit has a sharp center point and two cutting spurs that scribe the outside of the hole as it is drilled. This results in a clean, round hole with smooth sides. [3]

When they are used

When they are used with the proper technique, Brad Point bits create very clean and precise holes in wood. The most common use for a Brad Point bit is to drill pilot holes for screws. These bits are also excellent for doweling and can be used to make small mortises. [3]

Brad point materials

There are two types of brad point materials: those with a high speed steel (HSS) cutting edge and those with a carbide cutting edge. The HSS bits are less expensive but wear out more quickly, while the carbide bits are more expensive but last much longer.

If you’re drilling into hardwood or softwood, you’ll want to use an HSS bit.

Here’s a quick rundown of the different types of materials you might encounter and which type of bit is best for each:

- Wood: HSS

- Metal: Carbide

- Concrete: Carbide

- Stone: Carbide

As you can see, if you’re doing any type of serious drilling, you’re going to want to invest in a set of carbide bits. They might be more expensive upfront, but they’ll save you money in the long run by lasting much longer. [3]

Brad point sizes

There are three basic sizes of Brad point drill bits, which are distinguished by their shank diameters. The most common size is the quarter-inch Brad point bit, followed by the half-inch and three-quarter-inch sizes. Larger bits exist but they are less commonly used.

The different sizes of Brad point drill bits have different applications. Quarter-inch bits are typically used for drilling small holes in softwoods, while the larger sizes are better suited for hardwoods or metals. [3]

Tear-out

When you’re drilling into wood, there are two main types of tear-out: horizontal and vertical. With a brad point bit, you’ll get much cleaner holes with less tear-out. This is because the tip of the bit penetrates the wood before the cutting edges, so it’s easier to control where the hole goes.

In general, brad point bits are better for drill press applications or when you need to make very precise holes. If you’re just drilling some quick pilot holes, any type of drill bit will do. But if you want clean, precise holes in wood, a brad point bit is your best bet. [3]

Can Brad Point Drill Bits be Sharpened?

The good news is that, yes, brad point drill bits can be sharpened! You’ll need to use a sharpening stone or file to keep the bit’s cutting edge in top condition. However, it’s important not to over-sharpen the bit – too much of a keen edge can make it more likely to break.

If you’re not confident in your ability to sharpen the bit yourself, you can always take it to a professional. They will have the tools and experience necessary to get your brand point drill bit back into working order. [4]

Can Brad Point Drill Bits be Used on Metal?

Typically, brad point drill bits are only used on wood. That’s because the tip of the bit is designed to create a clean, precise hole in wood without splintering it. However, there are some brad point drill bits that can be used on metal. These types of bits have a slightly different tip design that helps them to cut through metal without creating too much friction and heat.

If you’re not sure whether or not your brad point drill bit can be used on metal, it’s always best to check the manufacturer’s instructions before using it. [4]

How to use a brad point drill bit

Now that you know what a brad point drill bit is and what it’s used for, let’s go over how to use one.

First, you need to decide what size bit you need. Brad point bits come in many different sizes, so make sure to pick the right size for your project.

Once you have the correct size bit, it’s time to start drilling. To do this, first find the center of your workpiece. Once you have found the center, align the tip of the drill bit with the center mark.

Now apply pressure to the drill bit and start drilling slowly. As you drill, keep an eye on the progress of the hole. If the hole starts to wander off course, stop and realign the drill bit.

Once you’ve drilled through the workpiece, remove the drill bit and check the quality of the hole. If necessary, use a file or sandpaper to clean up any rough edges. [3]

Advantages of Brad Point Bits

Ideal Tools for Working With Wood

There are several advantages to using Brad Point drill bits as opposed to other types of drill bits. One of the most notable advantages is that Brad Point bits create very clean and precise holes in wood. This is due to the fact that the tip of a Brad Point bit is much sharper than that of a standard twist drill bit, and it also has two cutting spurs that help keep the bit from wandering as it drills. [2]

Creates Cleaner Holes

This is especially important when working with wood, as you want to avoid any chipping or tears along the edges of your holes. Brad point bits create cleaner, more precise holes than other types of drill bits.

They’re also less likely to wander off course, so if you need to drill a hole in a specific location, a brad point is your best bet. [2]

Long Shelf Life

This means that your bit will last for a very long time, even with frequent use. In fact, many users report that their brad point bits last much longer than other types of drill bits. [2]Disadvantages of Brad Point Drill Bits

Cost More

The main disadvantage of Brad Point drill bits is their cost. They are more expensive than ordinary twist drill bits, so you’ll have to decide if the extra cost is worth it for your project.

Another drawback of Brad Point drill bits is that they can’t be used with a power drill. If you’re looking for a bit that can be used with a power drill, you’ll need to choose another type of bit.

Finally, Brad Point drill bits are not good for drilling through metal. If you’re trying to drill through metal, you’ll need to use a different type of bit. [2]

Not Ideal for Enlarging Existing Holes

With that said, there are certain situations where a Brad point bit can be used to enlarge an existing hole. If the original hole was drilled with a smaller Brad point drill bit, then it’s possible to use a larger Brad point drill bit to widen the opening.

Very Difficult to Sharpen

If you’re looking for a drill bit that will stay sharp for a long time, a Brad point drill bit is not the best choice. These bits are very difficult to sharpen, and even when they are sharpened, they don’t stay sharp for long. [2]

Investing in the Proper Brad Point Drill Bit

Just as there are different types of drill bits for different purposes, there are also different types of Brad Point drill bits. The three most common Brad Point bits are:

- Standard Brad Point Bits: These are the most versatile and commonly used type of Brad Point bit. They can be used on a variety of materials, including wood, plastic, and metal.

- High-Speed Steel Brad Point Bits: These bits are designed for use on harder materials, such as stainless steel and cast iron. They are also capable of drilling at higher speeds than standard Brad Point bits.

- Carbide Tipped Brad Point Bits: These bits are designed for use on extremely hard materials, such as concrete and brick. They feature a carbide tip that is extremely durable and can withstand high drilling speeds.

When choosing a Brad Point drill bit, it is important to consider the material you will be drilling into as well as the speed at which you want to drill. By investing in the proper type of Brad Point bit, you can ensure that your drilling project is successful. [2]

Brad points vs Forstner bits

The main difference between a Brad Point and Forstner bit is the way they are able to cut through materials. A Brad Point bit has sharpened cutting spurs on its tip that help it to create clean, precise holes in wood. On the other hand, Forstner bits have a sawtooth-like cutting edge that helps them to drill more quickly through tougher materials like metal or plastic.

In terms of which type of bit is better for specific tasks, it really depends on what you need to do. If you need to drill large holes quickly, then a Forstner bit will be better suited for the job.

Ultimately, it’s up to you to decide which type of bit is best for your needs. If you’re not sure, it might be a good idea to try out both types of bits to see which one works better for you. [3]

Brad points vs spade bits

Spade bits have a single cutting edge, while brad points have two. This gives them a more precise hole, which is why they’re often used for doweling. Brad points also don’t wander as much as spade bits.

The downside to brad point bits is that they’re more expensive than spade bits. They’re also not as good at drilling through metal or hardwood. If you need to drill through either of those materials, you’ll want to use a spade bit instead.

Still, for most general woodworking tasks, a brad point bit is the best choice. If you’re not sure which bit to use, err on the side of a brad point bit – you can always use a spade bit if you need to, but you can’t use a spade bit if you really need a brad point. [3]

Brad points vs auger bits

If you’re wondering what the difference is between a brad point drill bit and an auger bit, it’s all in the tip. Auger bits have a sharp, screw-like tip that starts the hole and pulls the bit through as it bores. Brad point bits have a sharpened “brad” at the tip (thus the name) that also starts the hole, but instead of relying on a screw action to pull it through, they cut their own way through material.

This guide will cover everything you need to know about brad point drill bits, including:

- What materials are best suited for drilling with brad points?

- How do I choose the right size and style of brad point bit for my project?

- What are the benefits of using a brad point drill bit?

- How do I use a brad point drill bit correctly?

- …and more!

So whether you’re a complete beginner or you’ve been using power tools for years, this guide will give you all the info you need on brad point drill bits. [3]

FAQ

Why is it called a brad point bit?

The bit is named after its inventor, Brad Point. The brad point bit is one of the most common types of drill bits used today.

Brad Point drill bits are distinguished by their sharp, angular point. This design helps the bit to stay on track when drilling, making it ideal for use in woodworking.

Brad Point drill bits are also known for their clean holes. Because of the way they cut, these bits leave behind smooth sides and a flat bottomed hole. This is especially helpful when drilling pilot holes for screws.

Are Brad point bits better?

There is no simple answer to this question. It depends on what you are using the drill bit for. If you need precision and accuracy, then a Brad point bit is probably a better choice.

In general, though, Brad point bits are more versatile and can be used in a wider range of materials than standard twist drill bits. They are also less likely to wander off course when drilling, which makes them ideal for precise drilling applications.

Can you sharpen wood drill bits?

Yes, you can sharpen wood drill bits. The best way to do this is with a file or sharpening stone. First, identify the bevel angle of the bit. Second, use a file or sharpening stone to hold at that same angle while you sharpen the cutting edge of the bit. Finally, test the bit on a piece of scrap wood to see if it’s still working properly. If not, repeat the process until it is.

How do you know if a drill bit is for metal?

If you’re looking for a drill bit that can handle metal, you’ll want to look for one that’s specifically designed for that purpose. Metal drill bits have different construction and materials than other types of drill bits, so they’re better equipped to handle the tougher material. If you’re not sure which type of drill bit to choose, consult with a professional or ask at your local hardware store.

Do you need special drill bits for metal?

No, you don’t need special drill bits for metal. Any type of drill bit will work, but Brad Point bits are recommended because they’re specifically designed for drilling through metal. Brad Point bits have a sharp point that helps to prevent the bit from walking on the material surface, and they also have deep flutes that channel away chips as you’re drilling.

Useful Video: Newbie Tool Tip: Brad Point Drill Bits & Other Twist Bits

Conclusion

There you have it! Now you know everything there is to know about Brad Point drill bits. They’re great for drilling through metal and they can be used on a variety of materials. With the right bit, you can tackle any project.

Do you have any questions about Brad Point drill bits that we didn’t cover in this article? Let us know in the comments below and we’ll be happy to answer them for you. Thanks for reading! And until next time, happy drilling!

References

- https://www.toolstoday.com/g-22-the-brad-point-boring-bit#

- https://toolsowner.com/brad-point-drill-bits

- https://powertoolbase.com/what-are-brad-point-drill-bits/

- https://www.finepowertools.com/drills/brad-point-drill-bits/

Leave a Reply